science inhouse lab

- hardness

- MFI

- specific gravity

- tensile

- elongation

- ash content

rebase_edit new development

- antistatic

- antimicrobial

- fire retardant

- antirodant

- night glow

- antimicrobial

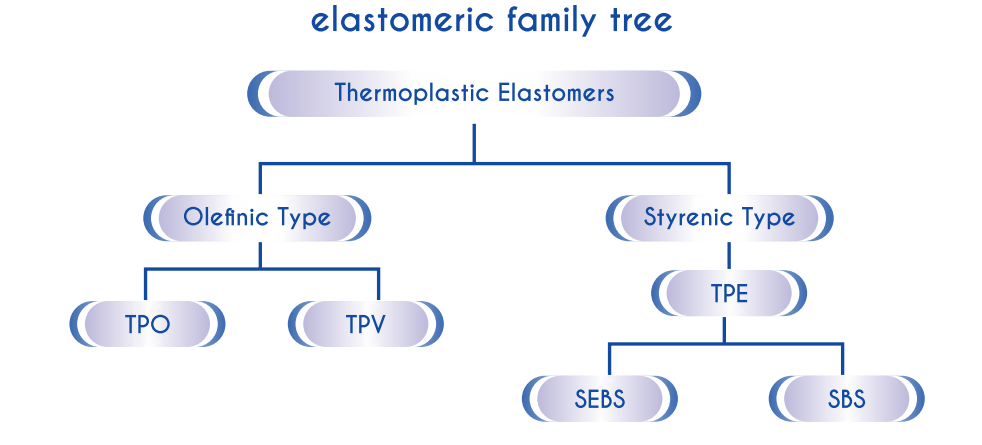

Thermoplastic Elastomers (TPEs) are a family of polymers with characteristics of rubber In-fact behaves like Thermoset rubbers, but are Easy to Process by mean of Injection, Extrusion & Blow molded, TPEs are economical product toward the Investment of Manufacturing compared to Vulcanized Ruboer. The Product is so Eco friendly to reuse multiple time, It also allows freedom to create design and innovative processing which thermoset polymers do not have. TPEs do not require drying. Curing or Vulcanization as required in Thermoset rubbers. TPEs share the best features of Plastic and the best of rubber making them very unique and incredibly versatile polymers for numerous applications

Speciality Compound has high comprehensive properties Good Chemical Resistance, Thermal Stability, Lou, Water Absorption, Lay Specific Gravity, Good Insulation Well suited for processing using Injection, Extrusion and blow-moulding Modification of Polymers by compounding with Talc Filled, Mineral Filled, Glass Filled, Flame Retardant and many more produces a substantial change in the properties of the base material Like PP, ABS, Nylon 6-66, PC Etc and gives to compositions based on the following properties like Mechanical Appearances Chemical Reustance and Excellent Moulding Properties

Application are in extensive range in Electronic appliances, Electrical accessories, Lighting Equipment's, Connectors, Automotive, Cooling Fan, Battery Cases also in household equipment.

Master batch (MB) is a solid additive for plastic used for colouring plastics (colour master batch) or imparting other properties to plastics (additive master batch). Master batch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin which is then cooled and cut into a granular shape. Master batch allows the processor to colour raw polymer economically during the plastics manufacturing process. masterbatches (MB)

copyright @2023 SADHBHAGYA POLYPLAST LLP All rights reserverd.

Design by Try Catch(vipul)